US Nisshin Shokai

1375 E. Woodfield Rd., Suite 250

Schaumburg, Illinois 60173

Tel: +1.630.912.2150

PRODUCTS AND SERVICES

- Food Ingredient Products

- Organic Ingredient Products

- Grain Equipment Products

- Ocean Freight Services

At Harada Sangyo, surpassing customer expectations through tailored solutions is our primary goal. We understand the importance of meeting the unique needs of our clients and are committed to offering customized equipment that combines our deep industry expertise with innovation. This dedication enables us to deliver highly effective and specific solutions. Our heritage of quality and a pioneering spirit guide us in being reliable partners, committed to personalizing our services to reflect the distinct requirements of each customer. We are grateful to all our partners for their trust. Together, we aim for excellence, crafting solutions that not only meet but exceed expectations.

Visit the Harada Sangyo website.

Description:

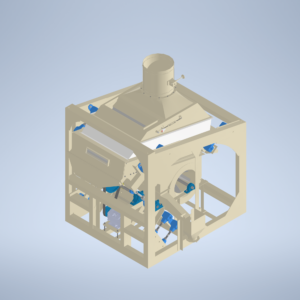

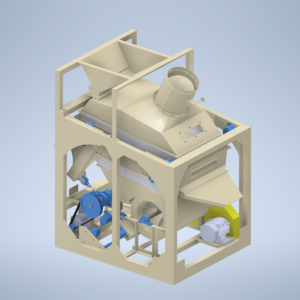

DS Model de-stoners offer exceptional precision in removing stones and heavy impurities from grains and other dry bulk materials. The airflow from the bottom of the deck lifts materials consistently, which is key for precision cleaning. Additionally, the top duct captures dust, helping to keep the workplace clean. Highly recommended equipment for markets sensitive to even the smallest stone contamination.

Available Models:

Description:

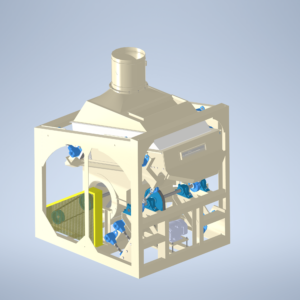

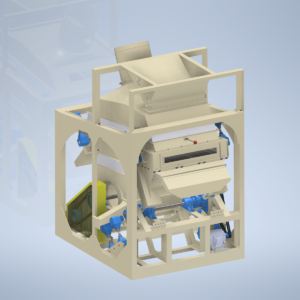

The KT Model gravity table excels in removing specific light materials from bulk products, particularly effective when used after an air screener. It specializes in precision sorting by density, ensuring minimal yield loss of good products while accurately eliminating undesired materials. This efficient separation process enhances the purity and the volume of the final output, making it essential for operations where quality and efficiency are paramount. This equipment is ideally suited where specific light materials need to be removed.

Available Models:

Description:

The RS model roll belt excels as a final step in the cleaning process, effectively removing remaining impurities after main screening. Designed to enhance the physical cleanliness of round materials like soybeans, it operates with minimal product loss, ensuring a very small cleanout percentage. By completing the physical aspect of cleaning, it reduces the burden on the color sorter, allowing it to maintain the accuracy of color sorting. Highly recommended for the premium market, this sorter is an essential tool for operations demanding the highest quality and efficiency.

Available Models: